Home Energy Audits Los Angeles - Whole Home Performance Check-Up

Our “Whole Home Performance Check-Up” uses building science to help us diagnose and create a treatment plan that will increase your home’s energy efficiency & comfort, lower your utility bills, reduce your carbon footprint, improve the indoor air quality, and extend your structure’s durability. It is so much more than a clipboard audit that some companies call an “Energy Audit”. California energy audit has three levels of our “Whole Home Performance Check-Up”: Fundamental, Diagnostic and Comprehensive. For energy audits in Santa Monica, Call Building Doctors at 323-646-2534 for a free phone consultation to see which one is right for you.

Here is how it works for the “Comprehensive” level:

Please see the services and retrofits section for examples of some of the work that we do.

For more information about Ladwp energy audits, call (323) 646-2534 or contact us today!

We interview the homeowner to see what specific problem areas we need to address and if there are any areas of the home that are preferred for us not to enter. We will also need copies of the last year's worth of utility bills. If you don't have copies, they are easily available from your utility company. Test day prep instructions will be left with you or emailed to you ahead of time. A Building Performance Institute (BPI) certified building analyst from The Building Doctors is assigned to each "Whole Home Performance Check-Up" and it takes at least 4-6 hours to collect all the data. It is not necessary for the homeowner to be home for the full test period but they are always welcome to stay because sometimes questions can arise that only you can answer. It helps to have big pieces of furniture pulled away from exterior walls and to run either the heat or AC for a few hours before we perform our tests. This ensures that the true temperature is absorbed into the framing and not just on the surface, which is extremely helpful when using the infrared camera. The infrared camera works best when there is a 10-degree difference between the inside and outside temperature. This can be hard to achieve during the Spring in Fall seasons but we will do the best that we can according to the weather.

Upon arrival on test-day, we will do an outside inspection of the property. We will measure the perimeter to confirm the square footage of the building and we will also measure the roof and all of the walls and windows for our energy modeling software. We will notate and photograph any issues with the exterior area. We will place one of our data loggers in your crawl space, which will record the humidity and temperature variances over a period of time. We will retrieve the logger before we leave and download the information for analysis.

Please note – The Building Doctors treat every building with the utmost care. Protective drop-cloths are placed on the floor and on all workspaces and we wear covers on our shoes and Building Doctors scrubs during our testing procedures. We respect your home and property and take great pride in protecting it during the test.

Some of the tests that are done in our Comprehensive "Whole Home Performance Check-Up" include:

This is an essential series of safety tests that we perform in all combustion appliance zones (CAZ) prior to performing Blower Door and Duct Blaster tests. The combustion analysis of gas appliances includes your water heater, furnace, cooktop, oven, and fireplace. These tests include gas leak detection, combustion draft pressure measurements, and carbon monoxide production & spillage evaluations for each vented appliance. These tests are conducted under worst-case conditions. Combustion safety test results must be acted upon according to the Combustion Safety Action Level table. A preliminary and post-installation safety inspection of all combustion appliances must be completed whenever changes to the building envelope and/or heating system are part of the work scope. These tests are part of the required procedures for a Building Performance Institute certified building analyst professional.

This test determines where there are air leaks in the building envelope. The Blower Door test involves fitting an adjustable fan inside a flexible nylon frame that's placed into an exterior door frame. The fan pulls the air out of the house, lowering the air pressure inside. The higher outside air pressure will gain access to the interior through unsealed cracks and openings (a process called infiltration), in places like door jams, window and floor moldings, and even recessed lighting fixtures. While the house is depressurized, we tour the house with a smoke puffer to find these holes in the building envelope. We document these sites in both written and picture form so they can be later identified for air sealing upgrades. The blower door fan is attached to a pressure gauge (Manometer), which measure airflow and the relative leakiness of a building. Air Changes per Hour (ACH) is a measurement of how many times the volume of air in a building leaves or enters the building, in one hour. We determine this by the fan pressure measurement and calculate cubic feet per minute (CFM) of airflow through the fan. Leakier houses have higher ACH's, and therefore higher cooling and heating expenses, and increased problems with comfort, indoor air quality, health, and moisture intrusion.

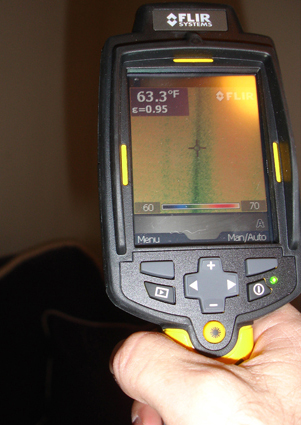

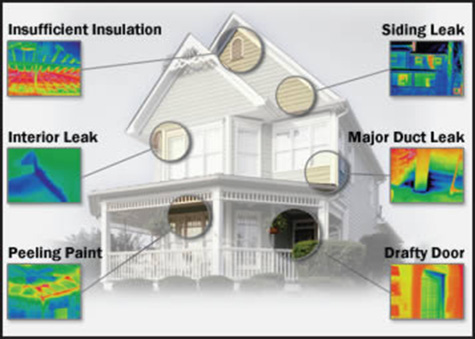

This test determines variations in surface temperature and is very effective in identifying areas needing repair without having to dismantle or uncover walls or other structural elements. While the house is still pressurized and there is a 10-degree temperature difference between the inside and outside, we tour the house with the infrared camera to check for air leaks, missing or poorly installed insulation, thermal bypasses, thermal bridges, and moisture issues. We document problem spots with both thermal imaging and digital cameras.

This is an interesting video that describes one of our processes for how we utilize this technology.

This diagnostic test combines a small fan and a pressure gauge to pressurize the HVAC duct system while temporarily sealing all heat and AC vents. The Duct Blaster accurately measures the air leakage of the duct system. Duct leakage can increase heating and cooling costs. The U.S. Department of Energy (DOE) reports that most U.S. homes have over 30% leakage, which contributes to health, safety, and comfort issues as well as wasted energy. There are further tests that can be performed to determine the location of the leaks and if the duct system can be patched with mastic (never duct tape) or if the entire system needs to be replaced. The focus on duct leakage is to test HVAC ducts that are outside of the building envelope. Leaky ducts in attics and crawlspaces have a great effect on energy loss, poor indoor air quality, and comfort issues.

Visual and measured inspection of attic insulation, potential roof leaks and other problem areas.

We check the flow rates of your shower, faucets, and toilets.

A visual inspection of the roof for solar energy potential as well as for overall condition, including possible moisture intrusion areas and maintenance issues.

We check the pressure in the ducts and temperature rise and compare it to manufacturer specifications.

We check the Heating, Ventilating, and Air Conditioning (HVAC) supply grills using our pressure pan diagnostic tool. We also check the rate of speed of the air coming from the vents using our handheld anemometer.

A visual inspection as well as the use of a data logger to determine moisture issues in your crawl space. The collected data will be included in the final report in graph form. This is the key to determining the need for a vapor barrier. We will also check for crawl space insulation and identify any problem areas.

As you see, our energy audit is just one of fifteen different tests that we do. This test consists of an inventory of the devices consuming power when not in use (phantom loads). We will provide a section in the final report detailing the kilowatt operational costs of each piece of equipment.

Existing light bulbs and fixtures can be replaced with more energy efficient longer lasting bulbs. The compact fluorescent bulbs on the market today use 75% less electricity and last 10 times longer than incandescent bulbs.

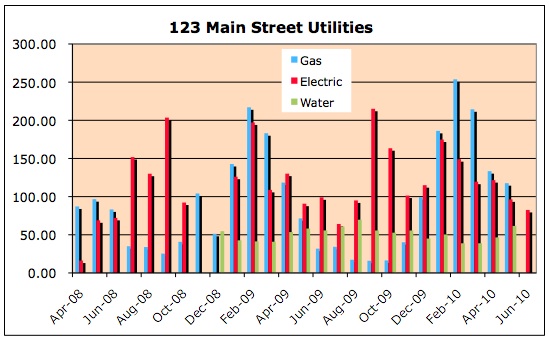

We will review the past year's electric and gas bills. A base load will be determined from the non-peak months. This is very important for comparison with future bills to determine the savings after remediation.

Prior to performing any home performance and diagnostic testing we visually examine the condition of the equipment. This inspection includes the condition of electrical, mechanical & fuel connections, maintenance status, filter condition, blower fan – if accessible, condensation drainage, duct connections, and duct configuration with respect to equipment size. Data taken from the serial # plates are included in the report. This provides us with vital information to determine the maintenance needs, system deficiencies, equipment capability, efficiency upgrade recommendations, and age of the equipment.

This test measures the ability of your exhaust fan to remove the air from your home. There are extremely quiet and efficient fans on the market today that can be changed with your old, loud. and energy draining fans. The duct length will be examined to determine if there are moisture issues being caused by too long of an exhaust run.

After completing our thorough audit and home performance tests, we’ll analyze the results to diagnose what issues exist and how to best correct them. You’ll receive a copy of the results in a clear, easy-to-understand report. You will also have a draft of your Home Energy Modeling System (HERS) score from the energy modeling software. A member of our team will review the findings with you and provide all the information you need to make informed decisions on our suggested “treatment plan”. You’ll understand the nature of the issues, as well as the corrective options. The HERS report lists the suggested retrofits and what the savings will be so you can determine what option is most financially beneficial to you.

As a Home Performance contractor, we can install all of the suggested retrofits. We follow a strict set of procedures to make sure the measures are installed correctly based on performance standards. Upon completion of the retrofitting work, we perform the diagnostic tests again and compare them to our test-in results so we can document the improvements we have made.

Please see the services and retrofits section for examples of some of the work that we do.